Swagelok tube fittings deliver a leak-tight, gas-tight seal in an easy-to- install, disassemble and reassemble form. The robust tube grip with patented, two-ferrule technology is resistant to vibration fatigue and withstands high pressures and temperature extremes.

Swagelok Cambridge has the capacity to support our biopharmaceutical, pharmaceutical, and biotechnology customers with the components and services they need to safely operate and maintain their required sanitary and sterile environment. Your business needs fluid systems that cannot leak, and Swagelok offers the fluid system solutions that reliably make the most sense yet are easy to disassemble for cleaning without compromising quality.

View Essential products that maintain a sanitary and sterile environment

Fittings Hoses Regulators Gas Distribution Systems Valves Quick-Connects Measurement Devices

Fittings

With burr-free internal surfaces and smooth thread flanks, Swagelok pipe fittings are precision manufactured to provide optimum sealing, minimize galling, and provide consistently tight-fitting installations.

Click Here

Swagelok TS series biopharmaceutical fittings feature enhanced drainability and cleanability to prevent bacteria from building up and contaminating processes. The unique design eliminates gasket extrusion to reduce the likelihood of fluid holdup.

Click Here

Swagelok tube fitting by sanitary flange fitting adapter provides a reliable, cost effective way to adapt from sanitary flange systems over to tube and pipe. Fast & easy to connect, speeds up installation and lower your total cost.

Click Here

Hoses

Smooth inner wall provides flow control and enhanced drainability for precision and cleanliness. Silicone cover washes down easily to prevent bacterial buildup, protects stainless steel braiding, protects against burns, and helps maintain process temperatures.

Click Here

Provides chemical compatibility, drainability, and precise flow control. Optional static-dissipative, carbon-black filled core, FDA-compliant and ECE R110 alternative fuel certified hoses for specialty applications.

Click Here

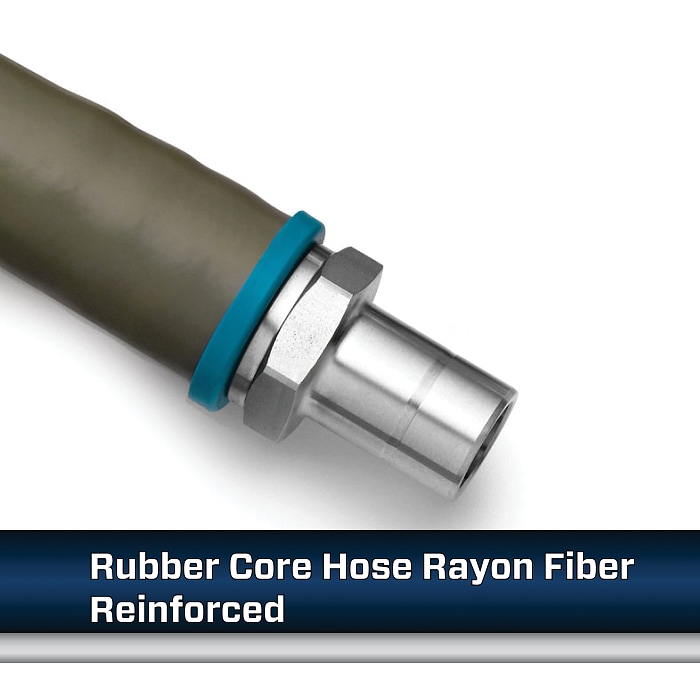

Rubber Core Hose Rayon Fiber Reinforced Multi-Purpose push-on hose. Smooth-bore Buna N core. Internal fiber reinforcement enhances hose pressure rating and ensures connection retention. Buna N cover resists abrasion. Bulk hose and end connections available for field assembly; custom assemblies also available.

Click Here

Chemically resistant, translucent, PFA flexible tubing is designed for use with both Swagelok PFA tube fittings and metal Swagelok tube fittings in low-pressure applications. The tubing’s translucence lets you see media. Smooth inner wall for flow control and drainability.

Click Here

Regulators

The TBRS series is a tank blanketing regulator which features 316L stainless steel metal components and FDA / USP Class VI compliant EPDM seals. The TBRS series has an adjusting screw for pressure adjustment. This Sanitary line of regulators are best used with clean / dry gases for purging, tank blanketing and other process support applications.

Click Here

The Swagelok® sanitary pressure regulators include the PRS series, a pressure-reducing regulator. These sanitary regulators are designed for medium high pressure and are available with sanitary clamp end connections.

Click Here

Swagelok RHPS series offers accurate pressure control in gas and liquid systems. Every RHPS series pressure regulator has three common design components which include a Loading mechanism, sensing mechanism, and Controlling mechanism.

Click Here

At Swagelok Cambridge, we have the right regulators to fit almost any situation. Our K series pressure regulators can maintain pressure and minimize droop over a wide range of pressures and flows.

Click Here

Our laboratory in-hood regulators are easily installed and provide precision pressure control for your experiments.

Click Here

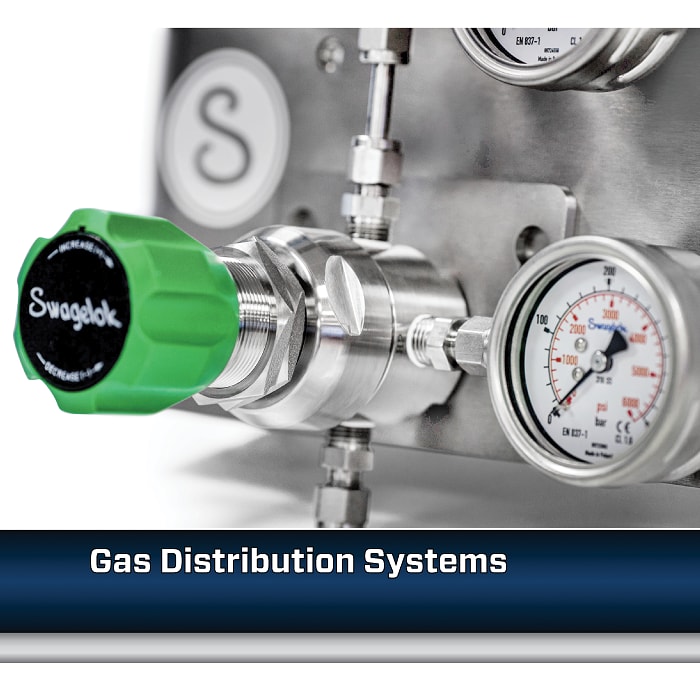

Gas Distribution Systems

Swagelok engineers build standardized, configurable gas delivery systems to help protect system operators, increase process uptime, and improve process accuracy and repeatability.

Click Here

Valves

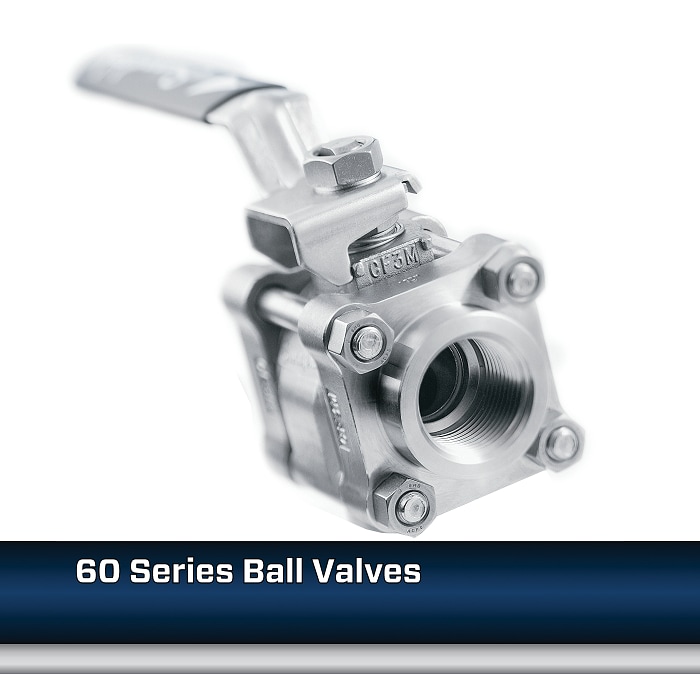

With a unique coned-disc, spring-loaded seat; live-loaded, two-piece chevron stem packing; and three-piece, swing-out design, 3-piece process/instrumentation 60 series ball valves are designed for reliability and low maintenance.

Click Here

Swagelok modified the valve construction and developed an innovative assembly process. The result is the 40G series ball valve, which features an expanded operating temperature rating, improved thermal cycling capabilities, and reduced potential for leaks.

Click Here

Quick-Connects

Connect quickly and with confidence. Swagelok's PTFE-Sealed Quick-Connects enable quick, simple operation without twisting, turning, or wrenching.

Click Here

Engineered to minimize spillage and air inclusion, our quick-connects are available in a wide range of configurations, stem and body connectors, including single-end shutoff and double-end shutoff models, and an array of end connections.

Click Here

Measurement Devices

Recommended to protect Swagelok dampened-movement bimetal thermometers from damage that could result from contact with pressurized, corrosive, flowing, viscous, or abrasive process fluids.

Click Here

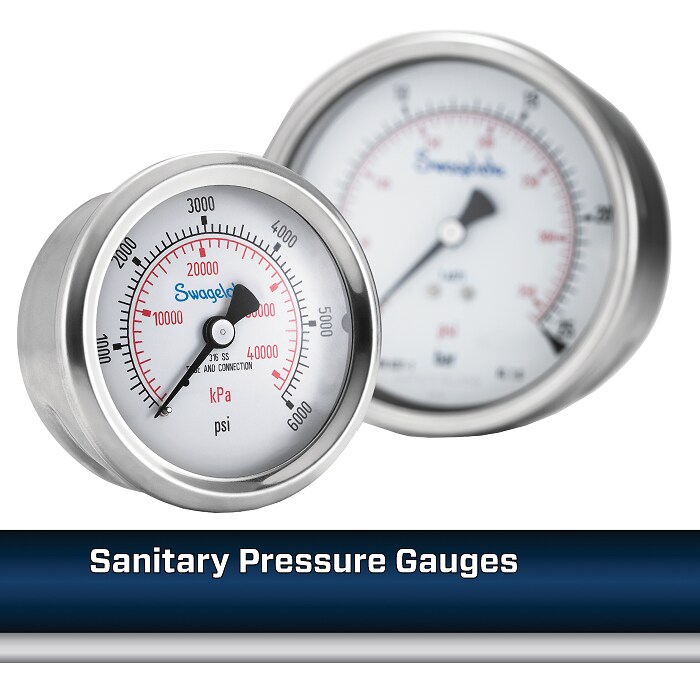

Swagelok gauges provide accurate pressure measurement for industrial, ultrahigh-purity, and sanitary applications. Pressure gauges with Sanitary Clamp or Tube Adapter ends eliminate alignment problems common with threaded pipe end gauges.

Click Here

Special Cleaning and Packaging

At Swagelok, the cleanliness chain starts with our commitment to ultrahigh-purity materials and ends with our cleaning and packaging specifications.

SC-11 Special Cleaning and Packaging Specification describes cleaning and packaging requirements for wetted system components that exceed standard cleaning and packaging requirements.

SC-10 Standard Cleaning and Packaging Specification defines the cleaning, lubrication, assembly, and packaging requirements for standard products and describes the practices used to meet these requirements.

The Support You Need

When designing a fluid control system for a new set-up or redesigning existing installations, our local Swagelok Field Engineers can bring expertise, optimizing these criteria:.

- Regulator sizing and selection

- Review P&ID drawings for application and translate into possible Swagelok solutions

- On-site system support and evaluation of fluid systems

- Connection reduction — fewer leak points

- Layout considerations made during design

- Proper product selection

- Proper pressure control & sizing

.ashx)