We continue to push the boundaries of ultrahigh-purity (UHP) valve performance, allowing tool OEMs and integrators to build manufacturing equipment that provides reliable, clean, and consistent flow at high temperatures and speeds.

In the Semiconductor industry, corrosive gases, extreme temperatures, and precision are critical process variables, combined with the ever-increasing need for speed, repeatability, and cleanliness. Count on Swagelok to help you meet your application needs today—and tomorrow. Our innovations continue to advance semiconductor manufacturing. They include ALD diaphragm valves tested to 100 million cycles, DE series springless diaphragm valves, DRP series fluoropolymer valves, benchmark-setting Swagelok VCR and Micro-Fit fittings, photovoltaic components cleaned and packaged for PV processing, and more.

Aggressive Chemistries Require Superior Materials

Cutting-edge processes demand even greater material characteristics. Swagelok‘s stainless steels and special alloys are engineered and blended to offer the maximum corrosion resistance, strength, and ductility. Our fluoropolymers offer stability at high temperatures, as well as chemical and corrosion resistance.

Supply Chain Control for Superior Cleanliness

We source and manufacture the best materials to ensure consistent quality. We go beyond the expected with processes like passivation and electropolishing for greater material purity. Then we clean and specially package our components to ensure your processes stay clean too.

Products and Services for Semiconductor

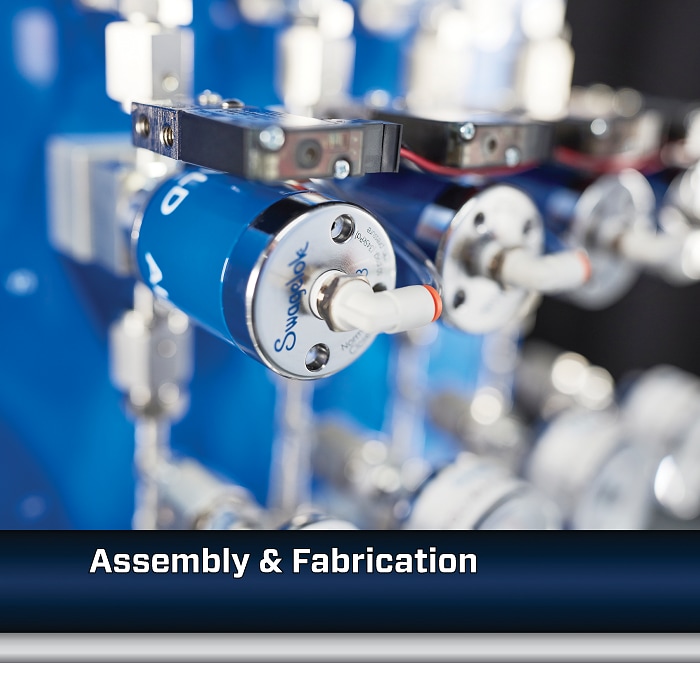

Swagelok can provide the support you need with custom subsystems and assemblies built to your exact specifications, ready to be installed.

Click Here

Our local Field Engineer will collaborate with you to ensure an understanding of the entire process, containing Swagelok and/or 3rd party components, and provide improvement recommendations to make sure your application is performing optimally.

Click Here

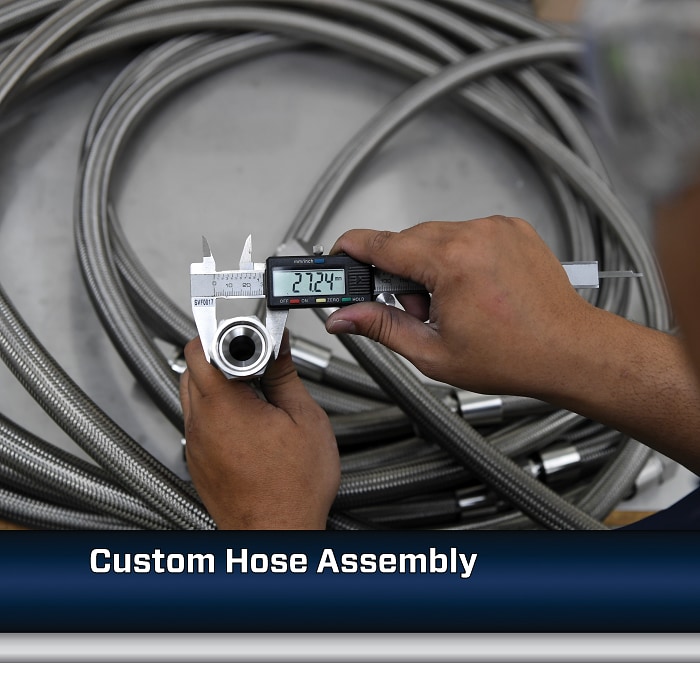

Find the right hoses for your semiconductor production environment. Our team of certified hose technicians will work with you to design and build the best possible hose for any application.

Click Here

In-depth, hands-on courses taught by experienced instructors help both new team members and industry veterans.

Click Here

Whether your processes are designed for ALD film deposition, etch, or photolithography, our specialists can conduct fluid system site surveys, hose advisors’ evaluations, or leak detection audits to make your facility safer and more efficient.

Click Here

Introducing the new ALD7 UHP Diaphragm Valve for ALD Processes

The Swagelok® ALD7 ultrahigh-purity (UHP) diaphragm valve has been designed, engineered, and manufactured to perform consistently from valve to valve, dose to dose, and chamber to chamber over an ultrahigh cycle life. You can rely on the ALD7 to deliver the high-quality, repeatable performance you expect from Swagelok® products.

Learn more about the ALD 7 technology

Avoid condensation or ice build-up

on your chiller hoses

Swagelok has combined their expertise in heat transfer and hose manufacturing, to develop a new insulation solution for low media temperatures. Swagelok hose insulation is designed to minimize heat loss over the length of the hose and keep the media temperature stable and consistent from beginning to end.