Find the right hoses for your semiconductor production environment. Our team of certified hose technicians will work with you to design and build the best possible hose for any application. Whether your system calls for insulated hoses for chiller applications to PTFE hose, metal hose and rubber hose options, we have the hose that will meet your needs. We stock hoses from 1/8 to 2 inches with a wide variety of end connections. Every hose assembly is built and tested onsite, warrantied, and delivered fast. Working with us, you’ll get the hose you need, with the quality, testing, certifications, and delivery you expect.

7 Areas to consider when selecting a hose

When you get ready to order hoses from Swagelok Cambridge, use the S.T.A.M.P.E.D. method to make sure you are getting what you need. The letters stand for Size, Temperature, Application, Material, Pressure, End Connection and Delivery.

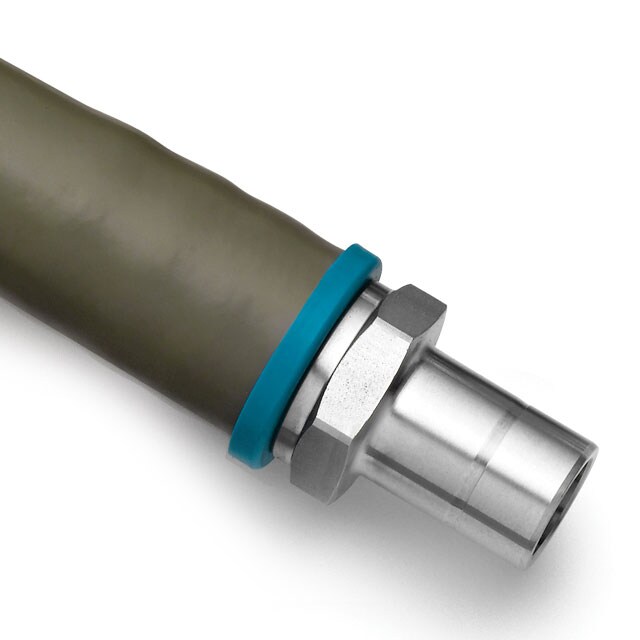

- Size: Swagelok offers hose in nominal diameters of 1/8 inch to 2 inches. Not all sizes are available in all types of hose. Size also is a consideration when you have concerns about space constraints. Hose assemblies with elbows and union ball joints may help resolve those issues.

- Temperature: What are the min. and max. temperatures the hose will be exposed to with regard to the media and environment?

- Application: Consider desired flow. Hose connection size, core tube construction and routed installation may all impact flow. What about movement? Will the hose be installed in a dynamic application? If so, this will require additional considerations.

- Material: Identify the system media, the environment and required drainability. This will help determine the materials of construction.

- Pressure: What are the min. and max. pressures (or vacuum) within and outside the hose assembly?

- End Connections: What is the style, type and orientation? Clarify any space constraints. Hose assemblies with elbows and union ball joints may help resolve these issues.

- Delivery: Do you have any special delivery requirements or specific quality, testing and packaging needs? Are any special markings required, such as tagging?