Understanding Time Delay

Ensuring an Accurate Result in an Analytical Instrumentation System

Understanding and Measuring Time Delay

Process measurements are instantaneous, but analyzer responses never are. From the tap to the analyzer, there is always a delay. Unfortunately, this time delay is often underestimated or not accounted for or understood. Time delay in sample systems is the most common cause of inappropriate results from process analyzers.

In many cases, it is invisible to analyzer specialists and technicians, who are focused on the necessity of making the sample suitable for the analyzer. It is not unusual for analyzer specialists to assume that the analytical measurement is instantaneous. In fact, sample systems often fail to achieve the industry standard of a one-minute response.

As a general rule, it’s always best to minimize time delay, even for long cycle times, but delays extending beyond the industry standard are not necessarily a problem. The process engineer determines acceptable delay times based on process dynamics.

Delays become an issue when they exceed a system designer’s expectations. A poor estimate or wrong assumption about time delay will necessarily result in inferior process control.

This article is intended to enhance understanding of the causes of time delay and to provide the tools required to calculate or approximate a delay within a reasonable margin of error. We will also provide some recommendations for reducing time delay. The potential for delay exists in the following sections of an analytical instrumentation (AI) system (Figure 1): process line, tap and probe, field station, transport line, sample conditioning system, stream switching system, and analyzer.

Process Line, Tap Location, Fast Loop, and Transport Lines

Generally, from the standpoint of time delay, it is best to locate the tap as close to the analyzer as possible, although there are other variables to consider. For example, the tap should be located upstream of sources of delay, such as drums, tanks, deadlegs, stagnant lines, or redundant or obsolete equipment. Further, the tap location should provide enough pressure to deliver the sample through the transport lines or fast loop without a pump, which is expensive and introduces another variable.

In many cases, the analyzer engineer, technician, or analyzer specialist may not be able to dictate the location of the tap. He or she may have to make do with an existing tap location, and, often, in addition, an existing analyzer shed location.

If the tap is at a long distance from the analyzer, a fast loop is recommended as a means of quickly delivering fluid to the analyzer. If properly designed, flow in the fast loop will be much faster than flow in the analyzer lines.

To calculate time delay in the transport lines, fast loop, or process line, use these equations:

Fluid velocity = volume flow rate / line volume per unit length

Time delay = line length / fluid velocity

Table 1 contains volume per unit length for standard size tubing and pipe. Flow rate typically is measured, not calculated.

Table 1. Volume conversions for standard sized tubing and pipe.

| Tube | Volume | Pipe | Volume |

| 1/8 in. tube | 1 cm3/foot or 2.5 cm3/m | 1/8 in. pipe | 7 cm3/foot or 23 cm3/m |

| 1/4 in. tube | 5 cm3/foot or 17 cm3/m | 1/4 in. pipe | 14 cm3/foot or 46 cm3/m |

| 1/2 in. tube | 25 cm3/foot or 82 cm3/m | 1/2 in. pipe | 48 cm3/foot or 151 cm3/m |

Example #1: Time Delay for Liquid in Transport Line

Consider a transport line with a flow rate of 5 liters per minute through 100 feet of one-half inch tubing.

Flow rate = 5 liter/min or 5,000 cm3/min

Line volume per foot (½ inch tubing from Table 1) = 25 cm3/ft

Liquid velocity = 5,000 cm3/min / 25 cm3/ft

Liquid velocity = 200 ft/min

Time delay = 100 ft / 200 ft/min

Time delay = 0.5 min or 30 s

Conclusion: This transport line meets the general industry specification of a one-minute response.

Example #2: Time Delay for Gas in Transport Line

The equation for calculating time delay for a gas in any section of the line contains an additional variable for pressure. Gas is compressible. A larger or smaller amount of gas can be compressed into the same amount of space. Therefore, flow rate in a fixed volume (the tubing) will change with pressure. The higher the pressure, the slower the flow.

Gas velocity = (volume flow rate / line volume per unit length) x (pressure at flowmeter* / pressure in the process line)

Time delay = line length / flow speed

*Pressure must be taken at the same place as the flow rate is measured. The flowmeter is usually positioned near the disposal.

Consider the sample being pulled from a process line at 285 psig, and then transported through the same transport line as described in Example #1 with the flowmeter venting to atmospheric pressure (~15 psia). Pressure must be entered in absolute pressure, not atmospheric. So a pressure reading of 285 psig must be adjusted to 300 psia.

Gas velocity = (5,000 cm3/min / 25 cm3/ft) x (15 psia / 300 psia)

Gas velocity = 200 ft/min x (1/20)

Gas velocity = 10 ft/min

Time delay = 100 ft /10 ft/min

Time delay = 10 min

Conclusion: This same transport line design for a gas application does not meet the one-minute goal due to the process pressure of 285 psig. To overcome this condition, a regulator must be installed at the tap location to reduce the pressure within the transport line. For this example, the regulator will be set to 15 psig or 30 psia.

Gas velocity = (5,000 cm3/min / 25 cm3/ft) x (15 psia / 30 psia)

Gas Velocity = 200 ft/min x (1/2)

Gas velocity = 100 ft/min

Time delay = 100 ft / 100 ft/min

Time delay = 1 min

Conclusion: The transport line is now 10 times faster with the installation of a regulator at the process tap. It now meets the one-minute response specification.

Probe

In most analytical instrumentation systems, another source of time delay is the probe. The larger the probe’s volume, the greater the delay. Volume will be affected both by the length and width of the probe.

The probe should be long enough to reach to the “middle third” of the process line diameter, where the stream moves the fastest and provides the cleanest, most representative sample. However, it should not be any longer than necessary.

In addition, the probe must be strong enough to withstand the environment within the process line. However, it should not be too large because time delay is directly proportional to the internal volume. In many applications, one-half inch pipe is used.

Fluid velocity in the probe cannot be measured directly but it can be calculated. It is sometimes assumed – incorrectly – that velocity in the probe is approximately the same as in the transport lines. In some cases, the difference is quite dramatic because the size of the tubing or pipe is different. In addition, in the case of a gas, higher pressure in the probe as compared to the transport lines means slower flow.

Remember, in the case of a gas, the higher the pressure, the slower the flow. One way to speed up flow in an AI system is to lower the pressure.

Example #3: Flow Rate for Liquid in Probe

To calculate the time delay in a probe, we must first determine fluid velocity in the probe. The equations for liquids are:

Fluid velocity in probe = volume flow rate in process line / volume per unit length of probe

Time delay = probe length / fluid velocity in probe

For the transport line explained above, consider a probe that is made from 18 inches (1.5 feet) of one-half inch schedule 80 pipe.

Flow rate in process line = 5 liter/min = 5,000 cm3/min

Probe volume per foot (½ inch pipe) = 46 cm3/ft*

*From Table 1.

Fluid velocity probe = 5,000 cm3/min / 46 cm3/ft

Fluid velocity probe = 109 ft/min

Time delay = 1.5 ft / 109 ft/min

Time delay = 0.014 min = 0.8 sec

Conclusion: The time delay in this probe application of less than a second is minimal. Combined with the outcome of Example #1, the total time delay for the liquid sample is 30.8 seconds, which is within the industry standard of one minute.

Example #4: Flow Rate for Gas in Probe

Many times, the gas pressure within a probe is much higher than the pressure within the transport line since it cannot be adjusted until it reaches a regulator in the field station. The formula for a gas sample in a probe is the same as for a liquid sample but with an additional variable to account for pressure.

Gas velocity in probe = (volume flow rate in process line / volume per unit length of probe) x (pressure at the flowmeter1 / pressure in probe2).

1 Flowmeter in the transport line.

2 Pressure in the probe is the same as pressure in the process.

If we plug in same inputs used in Example 3, we get:

Gas velocity in probe = (5,000 cm3/min / 46 cm3/ft) x (15 psia /300 psia)

Gas velocity in probe = (109 ft/min) x (1/20)

Gas velocity in probe = 5.45 ft/min

Time delay = 1.5 ft / 5.45 ft/min

Time delay = 0.27 min = 16.5 sec

Conclusion: Using this probe in conjunction with the transport line from Example #2 will result in a response of one minute and 16.5 seconds, with the regulator in the field station. Since the probe is before the regulator, pressure in the probe cannot and/or the flow rate in the transport line must be increased.

Field Station

In the case of gas, a field station is used as a means of reducing pressure in the transport lines or fast loop. Given the same flow rate, time delay in the transport lines is reduced in direct proportion to the reduction in absolute pressure. At half the pressure, you will get half the time delay.

The field station is located as close to the tap as possible. The sooner the pressure is dropped, the better.

In the case of a liquid sample, a regulating field station is not employed. It is better to keep liquids at high pressure to avoid the formation of bubbles.

In the case where a liquid sample will be analyzed as a gas, a vaporizing regulator may be used at the field station. A vaporizing regulator will cause considerable time delay. As the fluid changes from liquid to gas, volume will increase dramatically. The rate of increase will depend on the liquid’s molecular weight.

Typically, the measured vapor flow after the regulator will be >300 times the liquid flow before the vaporizing regulator. For example, with a vapor flow of 500 cm3/min., the liquid flow may be less than 2 cm3/min. Therefore, the liquid will take 25 minutes to travel through 10 feet of one-quarter inch tubing. To reduce this time, we must reduce the volume of the tubing preceding the regulator. For example, with only one foot of one-eighth inch tubing, it would take only 30 seconds for the liquid to reach the regulator. To this time, however, we must add time delay in the probe. The narrower the probe, the faster the response.

Another means of attaining a faster response would be to place the regulator closer to the analyzer location. In Figure 2, the regulator is located after the fast loop filter with a second liquid fast loop ensuring that good liquid flow continues right up to the vaporizing regulator. The objective is to minimize slow-moving liquid volume going to a vaporizing regulator.

Stream Switching

From a time-delay perspective, stream switching assemblies must work fast, quickly purging old samplematerialwhile moving the new stream to the analyzer. Double block and bleed (DBB) valve configurations, which are available today in conventional components or miniature, modular designs, provide a means of switching streams with minimal deadlegs and no cross-stream contamination from leaking valves.

A traditional DBB configuration is the cascading DBB (Figure 3), which eliminates deadlegs by using a second block valve instead of a tee piece.

One problem with the DBB cascading configuration concerns the tortuous flow path which leads to pressure drop and slower flow. Pressure drop may be estimated by looking up the product’s Cv, which is a measure of the resistance to flow. The lower the Cv, the greater the pressure drop, resulting in a lower flow rate.

In the DBB cascading configuration, the primary stream – Stream 1 in Figure 3 – does not cause excessive pressure drop but Stream 2, Stream 3, and so on create increasing amounts of pressure drop and a longer flow path, resulting in longer and longer travel times to the outlet.

The result is inconsistent delivery times from the different streams, making it difficult to set consistent purge times for all streams.

The DBB configuration with an integrated flow loop (Figure 4) enables all the advantages of the DBB cascading configuration while ensuring minimal pressure drop consistently across all streams. The Cv for each stream – and therefore the delivery time for each stream – will be the same. Note that a component with a Cv of 0.3 will cause one-third the pressure drop of one with a Cv of 0.1.

Sample Conditioning System

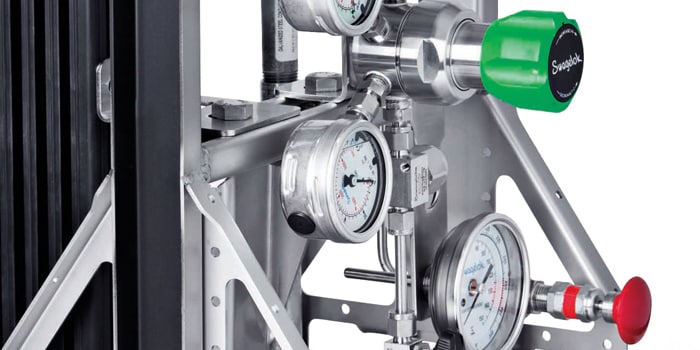

The sampling conditioning system prepares the sample for analysis by filtering it, by ensuring it is in the right phase, and by adjusting pressure, flow, and temperature. The components employed are numerous, including gauges, regulators, variable area flowmeters, flow controllers, check valves, control valves, and ball valves.

These are relatively small components. Frequently, miniature modular components are used. These are top-mounted components manufactured to ANSI/ISA 76.00.02 standard, according to the New Sampling/Sensor Initiative (NeSSI).

Like the stream switching valves, the critical matter here is not internal volume so much as pressure drop. When choosing components, you should compare the Cv provided by the manufacturer.

Other components used in the sampling conditioning systems, such as filters, knockout pots, and coalescing filters, may cause significant time delay because they allow incoming samples to mix with old samples. To clear out a filter or knockout pot – so 95 percent of the old sample is gone – requires three times the volume of the component. That’s assuming the inlet and outlet are adjacent, as in Figure 5.

Consider a filter with an inlet and outlet configured as in Figure 5: If the flow rate is 100 cm3/min and the filter’s volume is 100 cm3, it will take three minutes to ensure that 95 percent of the old sample has been flushed out. Therefore, to ensure an accurate sample, three minutes must be added to the time delay calculation for this AI system.

These same formulas may be applied to mixing volumes in the process line.

Analyzer

As a rule of thumb, a gas chromatograph will take five to 10 minutes to analyze the sample. Infrared and ultraviolet analyzers work much faster, completing analyses within seconds. The amount of time required for the analyzer to process a sample should be known to the analyzer specialist, technician, or engineer. That time will be added to the estimates discussed above for the total time delay from tap through the analyzer.

Conclusion

The total time delay as calculated with the tools above should provide an estimate within a reasonable margin of error. Remember that it is the total time from the process being monitored to the analyzer that matters, and that all components making up this delay must be added to the total.

The above discussion should alert analyzer specialists to any incorrect assumptions about the sample time, particularly as concerns typical trouble spots, such as the probe or a vaporizing regulator in the field station. It should enable analyzer specialists, in collaboration with their fluid system provider or consultant, to make intelligent choices about components and configurations in regards to the location of the tap, fast loop set-up, appropriate tubing diameters, and stream switching configurations. Time delay is an issue that deserves the analyzer specialist’s close scrutiny. Incorrect assumptions will undermine all the analyzer specialist’s hard work and render the expensive analyzer itself useless.

Resource

For more information, see the Swagelok book Industrial Sampling Systems (2013), the definitive sampling systems reference guide by expert Tony Waters.