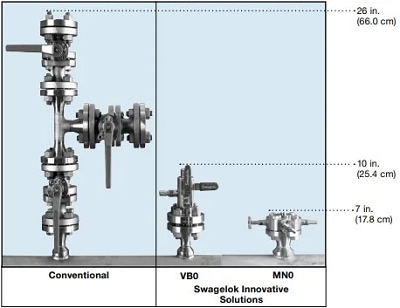

Standard valves can take up a good amount of space, especially when you need two or three in an assembly. To meet that challenges, we offer the process interface valves which gives you the footprint of one valve while doing the job of two or three valves. The compact size and reduced weight minimizes space envelope and support structure required. This one-valve configuration also provides the advantage offers fewer potential leak points. While not one of the most common valves you'll encounter, it's a great option to know about when you need it, and the single-source unit reduces maintenance time and cost.

Learn how to isolate industrial fluid systems with blocks valves.Features

- Valves and fittings use materials selected in accordance with NACE MR0175/ISO 15156

- Some materials offered are compliant with NORSOK M650

- Process interface in one compact ball/needle/ball valve assembly. Three-piece, bolted-body (VB03 series) or one piece forged body (VB04 and VB05 series) construction

- Flange connections compatible with ASME B16.5, NPT connections compatible with ASME B1.20.1

- Anti-blowout valve stems and needles

- Non-rotating needle vent valve

- Self relieving ball cavity

- Fire safe design

- Anti-static design

- Every process interface valve is tested hydrostatically to a requirement in accordance with API 598 and BS EN 12266-1

Our selection includes:

Installation Advantages

- Fewer leak points

- Smaller compact design

- Weight reduction of up to 75%

- Reduced installation time

- Reduced vibration stress

- Reduced fugitive emissions

- Low Emissions certification per API 641 and API 624 available

- Integral Swagelok tube fitting (connection options)

Swagelok Tube Fittings can be Integrated Directly into Double Block and Bleed and Monoflanges

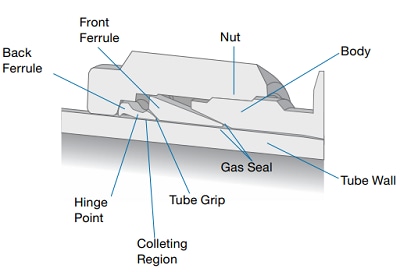

Swagelok tube fittings have a grip-type design that uses a unique “hinging and colleting” action to achieve optimal performance in three key areas:

- Tube grip—hinging and colleting action provides more direct tube contact/gripping support

- Gas seal—burnishing/polishing action of the front ferrule creates concentrated zones of contact on the tube and on the body bevel for a stronger seal.

- Vibration resistance—the colleting region better isolates stress risers at the tube grip to resist bending, deflection, and vibration.

Have Questions?

Our live chat provides support for all your fluid management solutions - from high-quality Swagelok Products, to application support and other services. Speak with a Swagelok Cambridge specialist right now!

.ashx)