A companion piece to Swagelok jacketed tubing, the Swagelok jacketed tube connector is designed to connect jacketed tubing systems while protecting tubing from external degradation in corrosive environments. The jacketed tube connector’s patent-pending design combines proven tube fitting technology with an O-ring seal and an innovative, environmental jacket seal nut, providing a leak-tight seal on the stainless steel core of the jacketed tubing and a water-tight seal on the outer diameter of the jacketed tubing.

- For use with 1/4, 3/8, and 1/2 in. jacketed tubing with up to 1/16 in. nominal jacket thickness

- Available in all standard tube fitting configurations

- Provides a leak-tight seal on the tubing jacket preventing environmental ingress

- Easy and rapid assembly

- Designed for repeated disassembly and reassembly

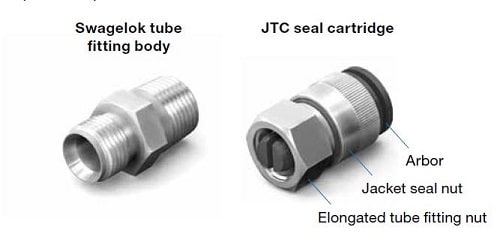

Components

The jacketed tube connector consists of two components— a standard tube fitting body and the JTC seal cartridge. The JTC seal cartridge is a preassembled cartridge that includes an elongated tube fitting nut containing front and back ferrules, and a jacket seal nut with jacket and vent O-rings, all on a disposable plastic arbor.

The preassembled JTC seal cartridge assures installers of the correct ferrule orientation and proper installation into the fitting body. Components are released only after the tube fitting nut is threaded finger-tight onto the tube fitting body.

CAD Files and Sales Drawings

Choose from more than 1 million Swagelok CAD templates and sales drawings in multi-lingual formats CAD templates are available in a variety of 2D or 3D file formats. Sales drawings are available in .pdf format. Search based on product names or part numbers.

"Safe Product Selection:

The complete catalog contents must be reviewed to ensure that the system designer and user make a safe product selection. When selecting products, the total system design must be considered to ensure safe, trouble-free performance. Function, material compatibility, adequate ratings, proper installation, operation, and maintenance are the responsibilities of the system designer and user.

|

Have Questions?

Our live chat provides support for all your fluid management solutions - from high-quality Swagelok Products, to application support and other services. Speak with a Swagelok Cambridge specialist right now!