Failed hose assemblies require time and resources you just don't have. It's better to be prepared by taking a preventive approach. Let the Swagelok® Hose Advisory Services team help. After an on-site plant survey, we review your systems and provide recommendations to improve your overall operation and reduce costly downtime. That's peace of mind that can only come from a trusted partner like Swagelok.

The benefits of this collaboration include:

Drive Facility Efficiencies - Save time and resources while being able to

focus on more pressing priorities.

Reduce Plant Maintenance Costs - Prevent costs associated with

continuously replacing the same problem

hoses, unplanned downtime

and wasted product.

Extend Hose Life - Save money through proper hose selection and installation,

because an optimally routed hose and end connection combination will have a longer life.

Master Hose Maintenance - Better predict when systems will need attention and understand what steps are the necessary to keep everything running smoothly with a customized preventative maintenance schedule.

Increase Safety - Keep your plant and processes safe, predictable and

dependable with a leak-tight products and best practices to reduce the risk

of injuries and environmental damage.

Why Swagelok Hose Advisory Services

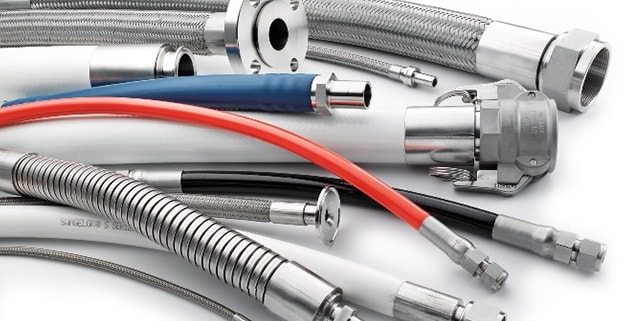

We know you are busy and can't afford downtime. We also know that hoses are often the most overlooked element—and among the most critical—of manufacturing operations. The Swagelok® Hose Advisory Services program combines consulting and an extensive range of product solutions—22 different hose types and 89 different end connections—for an unmatched variety of applications, including yours. Make managing your hose systems a worry-free experience with Swagelok® Hose Advisory Services.