An Introduction to Fittings: Identifying Thread Size and Pitch

Learn how to determine thread size and pitch for fittings in your small-bore industrial fluid system using the right tools, decreasing the chance of leaks or blowouts.

Tube Fitting Spec Update: Improving Safety and Performance

Learn why newly specified attributes for oil and gas tubing and tube fittings can help improve safety and system performance in platforms around the world.

Key Differences in Small-Bore Fittings

Learn the key differences between commonly available tube fitting types used in a variety of applications in this handy introduction to small-bore fittings.

Specifying High Performance CNG/LNG Fittings

Compressed natural gas (CNG) and liquefied natural gas (LNG) transportation applications require high-performance tube fittings that meet a number of important criteria. Learn what makes for an ideal CNG fitting or LNG fitting.

How an Industrial Hose Maintenance Plan Could Save Your Plant Thousands

Knowing the proper time to replace your industrial hoses can save your plant thousands in maintenance costs. Learn how to evaluate your systems and develop a preventive maintenance plan to manage the health of your hoses.

3 Steps to Hose Safety & Lower Plant Costs

Industrial hose safety is often deprioritized during regular plant maintenance. It is important hoses receive the attention they deserve—leaks and wear can put your facility at risk. Learn tips to avoid dangerous situations while lowering plant costs.

Maximizing the Life of Industrial Fluid System Components

The cost of replacing an industrial fluid system component goes beyond the price of the part. Learn how to lower system costs while maximizing the life of your components with preventive maintenance tips from the professionals at Swagelok.

Optimizing Hose Selection for Tire Curing Presses

Find out how Swagelok can help tire manufacturers optimize hose selection for curing presses, driving greater productivity and safety while eliminating downtime.

Solving Semiconductor Fabrication Challenges with Insulated Hoses

The right insulated hose solution can help solve some common challenges associated with the highly precise semiconductor fabrication process.

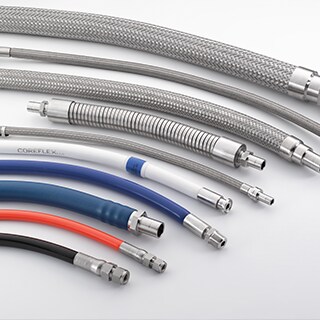

Reviewing Flexible Hose End Connection Types & Use Cases

Reviewing Flexible Hose End Connection Types & Use Cases Learn the types of tubing or flexible hose end connections most used across industries, from pharmaceutical to semiconductor, and how to assess and select products best suited for your specific application.

How to Select the Right Hose Reinforcement

Industrial hoses typically contain critical reinforcement layers that contribute to longevity and performance. Learn about different reinforcement layers types and which is best suited for different fluid system applications.

Industrial Hose Replacement: Core Tube Material

When selecting an industrial hose, the first place to start is the core tube—the hose’s innermost layer. Learn how to select the ideal hose for your application with information on core tube materials & wall construction from the experts at Swagelok.

How to Use a Regulator to Reduce Time Delay in an Analytical Instrumentation System

Time delay is often underestimated or misunderstood in analytical systems. One way to mitigate this delay is with a pressure-controlled regulator. Learn how manage your analytical system’s time delay with tips from the experts at Swagelok.

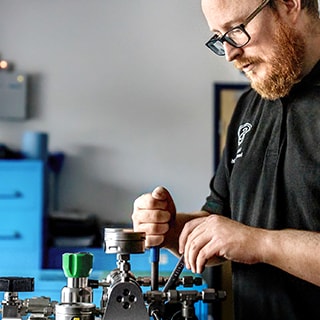

How Thorough Testing Ensures Reliable Regulator Performance

Have you ever wondered what testing goes into a product designed to operate in extreme conditions? Take a look behind the lab doors, following the development journey of RHPS Series industrial regulators rated for use at temperatures well below zero.

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

How to Flatten a Regulator Flow Curve to Reduce Droop

Droop is an issue for every pressure-reducing regulator. Learn how to minimize droop and flatten regulator flow curves with various dome loaded regulator configurations explained by Jon Kestner.

Back-Pressure Regulator Set-Up: Tips for Sampling System Engineers

Back-pressure regulators can effectively control upstream pressure within a sampling system process line—when set up correctly. Learn how to accurately design and build a process line with a back-pressure regulator.

Why Safe Industrial Pressure Regulator Performance Requires Rigorous Testing

Learn why robust pressure regulator testing can help verify proof of performance under the most strenuous, real-world industrial fluid system applications.

Valves 101: What Fluid System Pros Should Know

Industrial valves play an important role in controlling the flow of media in critical fluid systems. Learn more about valve types, their functions, and how to make the right selection.

How to Select Valves for Industrial Fluid Systems

Learn how to apply the practical STAMPED method to select the valves most suited to your industrial fluid or sampling system design applications.

How to Isolate Industrial Fluid Systems with Block Valves

The isolation of industrial fluid system lines prior to maintenance is vital to plant safety. One of the safest ways to isolate a fluid system line is to install two block valves. Learn how to design proper configurations for your system.

One New Valve. Three Reasons It Could Change Semiconductor Manufacturing

One New Valve. Three Reasons It Could Change Semiconductor Manufacturing Find out how the latest innovation in atomic layer deposition (ALD) valve technology is changing the game for high-tech semiconductor manufacturers.

Closing the Manufacturing Skills Gap: 3 Steps to a Well-Trained Team

With an aging industrial workforce nearing retirement, manufacturers are turning to younger generations to replace expert knowledge. Learn how to build an effective fluid system training program with expert advice from Swagelok.

Fluid System Training: Is Your Trainer Trained?

Fluid system training is critical in oil and gas applications around the world. Learn more about how to evaluate the right training opportunities from Swagelok.

Four Ways Training and Advisory Services Can Help You Bridge the Skills Gap

Learn how fluid system training and advisory services can help operators bridge a growing skills gap across several industries.

How Training Can Eliminate Risk on Oil and Gas Platforms

Proper training on critical fluid system activities is important on oil and gas platforms. Learn how the right training can help prevent accidents.

Why Materials Science Training Matters to Oil and Gas Instrumentation Engineers

Fluid system training is critical in oil and gas applications around the world. Learn more about how technical trainings can make a difference for your facility.

Your Industrial Fluid System Safety Checklist

Follow these best practices to enhance the safety of your industrial fluid system.

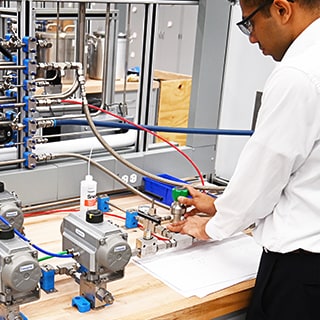

Field Engineering Q&A: What to Know for Better Fluid and Sampling System Performance

Swagelok Field Engineering Services can help fluid and sampling system operators solve issues from leaks to sampling inaccuracy and everything in between. Here’s everything you need to know about Swagelok Field Engineering.

Gas Plant Saves 90% on Labor, Eliminates Leaks

Leveraging years of experience and specialized equipment, Swagelok Calgary helped a major natural gas processor expedite its leak detection process, achieving a 90% reduction in required labor, among other benefits.

How to Improve Fluid System Performance

When fluid systems fail to perform safely and efficiently, plant productivity suffers. Swagelok can relieve the pressure of maintaining good system performance by providing expert guidance and helping to create a culture of continuous improvement.

Identifying Cost Savings in Utility Gas Systems

See how Swagelok Texas Mid-Coast provided on-site analyses of a major petrochemical producer’s aging utility gas system and uncovered savings of more than $2 million annually.

Swagelok Field Engineer Services: Improving Analytical Instrumentation

Worldwide, industrial facilities are feeling the pressure to increase profits despite the widening manufacturing skills gap. Swagelok field engineers can help remedy your fluid system challenges with training and expert evaluation services.

Industrial Virtual Visits: A New Form of “On-Site Experience”

Learn how Swagelok is adopting virtual headset technology to provide real-time troubleshooting, fluid system evaluation services, and more to customers when in-person visits are difficult to arrange.

Seven Tips for Effective Plant Turnarounds

A plant turnaround can be a big headache for a chemical plant or refinery—but it doesn’t have to be. Learn seven strategies for more effective turnaround management.

Tackling Practical Performance Issues in Fluid and Sampling Systems

Learn practical tips on how to improve the performance and accuracy of your fluid and sampling systems from Swagelok.

7 Tips for Building Safer Industrial Fluid Systems

7 Tips for Building Safer Industrial Fluid Systems When designing industrial fluid systems, plant safety must always remain top of mind. Learn how your team of engineers and technicians can reduce safety risks and maintain system uptime with essential fluid system building and design tips.

Small Footprint, Large Impact: How to Detect and Protect Against Gauge Failures

Learn to recognize the signs of a failing gauge and avoid risk to employees and costly downtime to make repairs.

Luxfer Hydrogen Fuel Cell Case Study

Swagelok’s spirit of collaboration and willingness to invest in an EC-79 certification enabled Luxfer to create fuel delivery systems to power 144 hydrogen fuel cell buses. Learn how Swagelok Manchester’s level of commitment drove innovation for Luxfer.

Meeting the Needs of Hydrogen Vehicles and Zero-Emissions Technology at ACT Expo

Clean transportation is important, and hydrogen vehicles require reliable infrastructure to become more viable and widespread.

Optimizing Component Selection for Hydrogen Fuel Cell Vehicles

Hydrogen transportation depends on reliable component specification and selection. Learn more from Swagelok.

The Anatomy of a Hydrogen Fitting

Learn why fittings designed specifically for hydrogen applications can help fuel cell vehicle OEMs and infrastructure developers achieve safer and more reliable fuel systems.

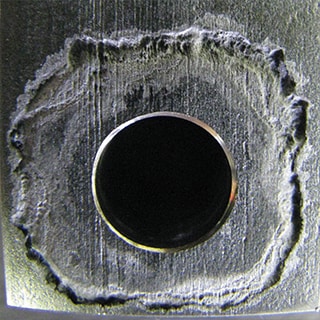

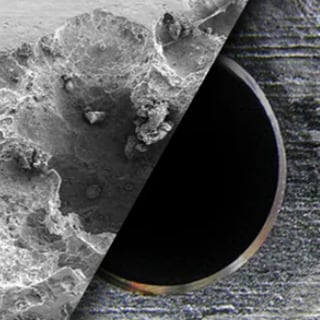

Pitting Corrosion vs. Crevice Corrosion

Stainless steel corrosion in tubing systems is a leading cause of profit loss for oil and gas companies every year. Learn how to identify & combat two main types of corrosion, pitting corrosion and crevice corrosion, with tips from Swagelok experts.

Material Matters: Selecting the Right Material for Corrosion Resistance

An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections. No wonder choosing corrosion-resistant material isn’t easy. Learn how to make choices right for your application.

4 Answers on Material Selection for Sour Oil and Gas Fields

As oil and gas production expands into sour environments high in hydrogen sulfide, material reliability becomes critical. Learn how proper material selection and adherence to NACE standards can keep your system running efficiently.

Cut Maintenance Costs with Enhanced Gas Panels

Learn how easy-to-use gas panels and an overall more efficient gas distribution and delivery system can help laboratories, refineries, and other facilities drive down maintenance costs.

Q&A: How to Optimize Your Gas Distribution System

Learn about common challenges that can hamper the safety and efficiency of important gas distribution systems and how a professional evaluation of those systems can provide long-term value.

Improve Gas Distribution Safety and Efficiency

Gas distribution systems are crucial for helping labs, test centers, and industrial facilities operate at peak efficiency. Learn more about optimizing gas delivery system health and safety, reducing costs, and equipping your team for success.

Identifying Cost Savings in Utility Gas Systems

See how Swagelok Texas Mid-Coast provided on-site analyses of a major petrochemical producer’s aging utility gas system and uncovered savings of more than $2 million annually.

Gas Delivery Knowledge Supports a Critical Cause

Learn how Swagelok engineers leveraged their knowledge in gas delivery and distribution to develop medical ventilators to aid in the event of a shortage during the COVID-19 pandemic.